Features

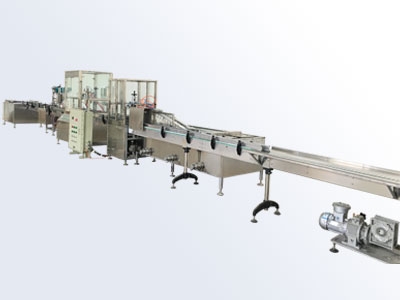

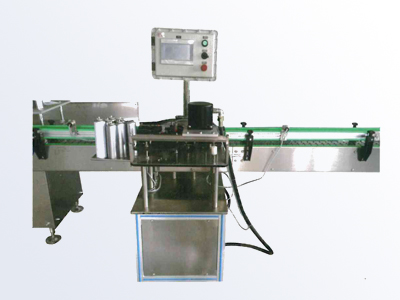

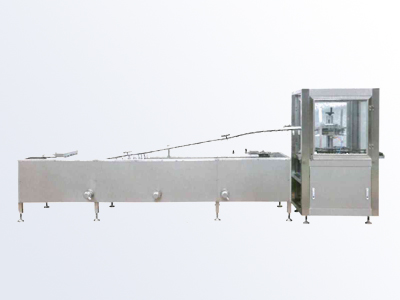

1. The machine is composed of unscramble bottles, upper L-valve, vacuum sealing, inflation, weighing, water bath leak detection, and outer cover. It is more convenient to increase or decrease the machine. It can be equipped with a fully automatic shrink packaging machine and a box sealing packing machine.

2. The equipment runs smoothly and reliably. It can be filled without jams, can be filled with bottles, and can be filled without bottles. The installation and disassembly of the whole machine is easier, and the production efficiency is high, and it is safe and reliable.

3. This type of product needs to be vacuumed and has a large inflation capacity, so the speed of the production line is restricted, generally 35-45 bottles/min/single line. Parallel line inflation mode can be used to increase the filling speed of the entire line.

Product application range:

This production line is designed for the filling of cassette furnace pots, lighter pots, oxygen tanks and other products.

TEL

TEL