Features:

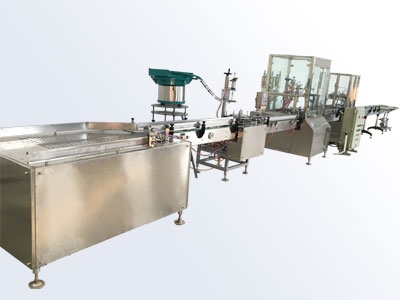

1. The machine is composed of a bottle unscramble workbench, an automatic valve release machine, an automatic vacuum sealing and inflator, an automatic detection system (water bath leak detection), an automatic nozzle buckle, an automatic mask buckle, a coding machine, and a packaging table.

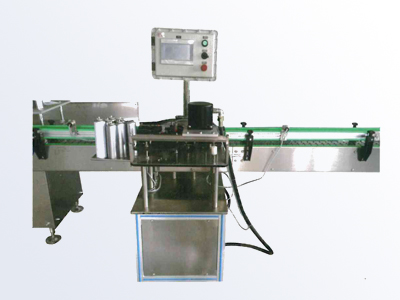

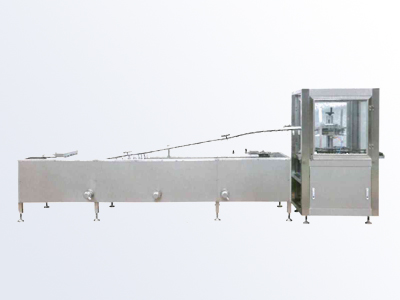

2. The assembly line absorbs foreign technology, comes with a vacuum system, and the sealing head adopts guided sealing. If the sealing quality is not high, the machine will automatically stop.

3. The inflation head adopts guided inflation, which is accurate, efficient and consumes very little gas.

4. The machine has the characteristics of high production efficiency, safety and reliability, simple operation and convenient maintenance.

5. The main seals and core components are all high-quality foreign products, the equipment is durable and stable.

6. Except for the explosion-proof variable speed motor used for the production line conveyor belt, the others are driven by compressed air with high safety factor.

Product application range:

This production line is suitable for the filling of oxygen, compressed air, nitrogen, cassette stove hot pot gas, mountain travel cans, and carbon dioxide gas.

TEL

TEL