Features:

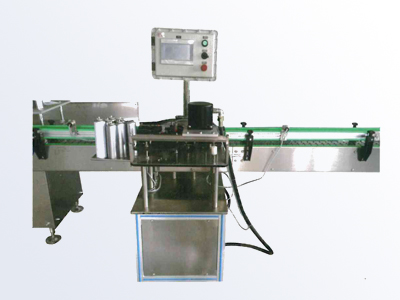

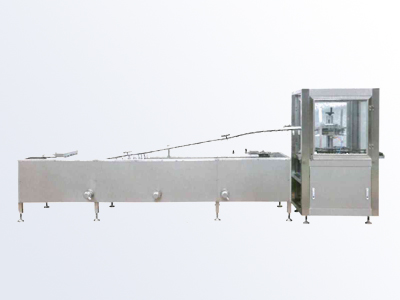

The automatic high-speed aerosol capping machine is an upgraded version of the ordinary capping machine, which is fast and efficient. It is used in conjunction with the high-speed aerosol filling line.

1. The automatic high-speed capping machine is composed of four parts: a crawling bucket capping machine, a tray selection, a track, and a capping host. The capping speed can reach 120 pieces/min.

2. Using Siemens PLC as the program control core, Snyder low-voltage components.

3. Advanced man-machine dialogue interface, there will be automatic alarm display when there is a failure.

4. The arranged lid of the hopper enters the material channel and slides directly into the gap of the star wheel.

5. The combined star wheel of the big cap machine sends the cap body and aerosol can to the capping station.

6. The lifting system of this machine can easily and quickly adjust the tank type of different heights, and can continuously and automatically press the caps. It is equipped with photoelectric detection for blocking, missing, missing, and missing bottles.

Product application range:

It is widely used in the placement of the outer cover of aerosol products in the fields of daily chemicals, medicine, cosmetics, industry, and chemicals. For example, self-painting, sunscreen spray, pesticides, physiological seawater nasal spray and so on.

TEL

TEL