Features:

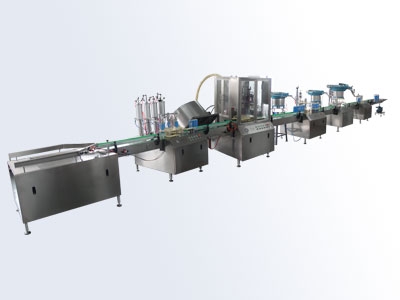

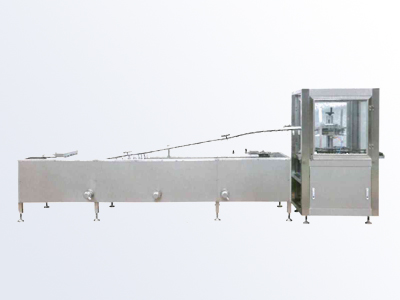

1. The machine is composed of a bottle unscramble table, an automatic filling machine, an automatic valve loading machine, an automatic sealing aerator, an automatic weighing and rejecting machine (optional), a water bath leak detector (optional), and an automatic nozzle loading machine (Optional), automatic large cover machine (optional), online inkjet printer (optional), sealing and packing (optional) and other equipment.

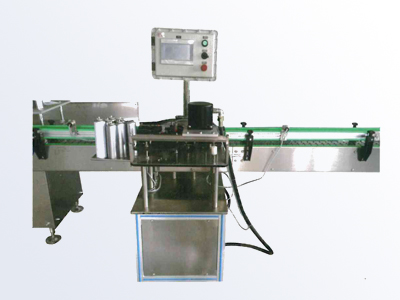

2. The filling system adopts the piston working principle, which is suitable for a variety of viscous liquids, with 2-4 filling heads, and the jog/auto mode can be switched freely.

3. The sealing head adopts guided sealing, if the sealing quality is not high, the machine will automatically stop; the inflating head adopts guided inflating, which is accurate, efficient, and consumes little gas.

4. According to customer needs, it can be equipped with automatic glass ball/steel ball machine, labeling machine, and tube sticking machine.

5. The conveying system of the whole production line can be designed according to the U-shaped rotating structure to save space.

6. The machine has the advantages of high production efficiency, safety and reliability, simple operation and convenient maintenance, and its main technical indicators fully reach the level of similar foreign products.

Technical Parameters:

|

Liquid filling capacity((ml) |

50-750 |

|

Liquid filling progress(%) |

≤±1 |

|

Inflation capacity(ml) |

50-750 |

|

Inflation accuracy |

≤±1 |

|

Seal size progress(%) |

≤2 |

|

Applicable aerosol can diameter(mm) |

35-65 |

|

Applicable aerosol can height(mm) |

90-315 |

|

Work pressure(Mpa) |

0.6-1 |

|

Air consumption(m³/min) |

3-5 |

|

Production capacity(Can/hr) |

1800-3600 |

TEL

TEL