Features:

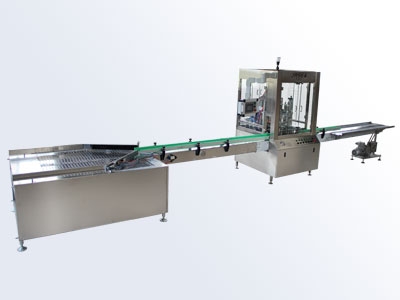

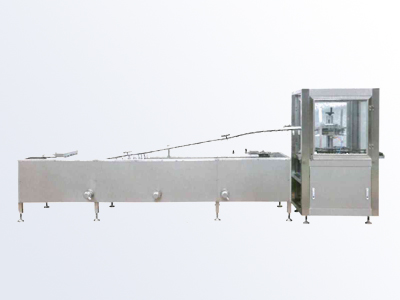

1. The complete configuration of the production line consists of a bottle unscrambler workbench, air blowing and dust removal machine, ultraviolet sterilization and disinfection machine, automatic valve system, oxygen replacement filling system, automatic internal pressure measurement, automatic water bath leak detector, automatic nozzle deduction machine, automatic It consists of 11 units of capping machine, inkjet printer and shrinking machine.

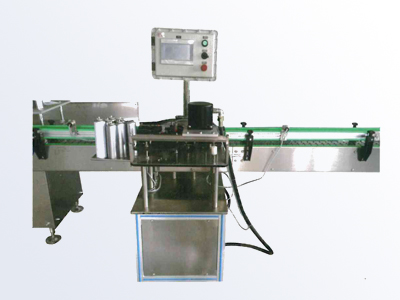

2. Using touch screen + PLC program control, digital precise control, simple and convenient.

3. The inflatable host adopts a combination of servo electric control + star wheel intermittent control. The star wheel can rotate 3 stations at a time and fill 3 bottles at the same time, which greatly improves the speed of the whole line.

4. The machine integrates the four core functions of vacuuming, charging, cyclic replacement, and sealing under the cover. The oxygen concentration after filling can reach more than 99.6%, with a high degree of automation and labor saving.

5. The production line can be upgraded to a 2-line and 1-line mode, which greatly increases the production speed and saves the customer's investment in equipment funds.

Product application range:

This production line is suitable for the filling of medical oxygen, compressed air, nitrogen, mountain tourism tanks, and carbon dioxide gas.

TEL

TEL